A New Precrystallization Kit Solves Chairside Adjustment Challenges

All interproximal and occlusal adjustments can now be completed chairside before final crystallization and glazing with everything included in the kit

David M. Juliani, DDS

For the past 2 decades, dentistry has been prodding materials science and manufacturers to leave the world of metal-based restorations in the past. Though the demand for esthetics is mainly patient driven, as providers we still desire and expect these materials to also be strong and durable. With these new products, the same questions inevitably seem to surface: Is stronger necessarily better? How strong is too strong? How do we treat these materials in their various stages? What burs should we use? Which speed? Which grit?

Since its introduction in 2009, IPS e.max® (Ivoclar Vivadent) has been the material of choice for posterior chairside CAD-based restorative procedures. The unique monolithic properties provide a functional, esthetic, and durable restoration. Fully crystallized, these restorations approach nearly 370 MPa of fracture resistance, which is almost three times what porcelain-fused-to-metal restorations (PFM) or full-contour porcelains have. Zirconia-based restorations can offer fracture resistance near 1,000 MPa, but often compromise on esthetics by appearing opaque. Because of this, the esthetics and strength of IPS e.max have made it the No. 1 chairside CAD material in the world. Unfortunately, this strength can pose some challenges chairside when adjustments or enhancements are needed. By working together, Brasseler and Ivoclar have solved this issue by offering the new Pre-Crystallized e.max Adjustment Kit.

With IPS e.max and chairside CAD, we have the luxury of working with the material in the precrystallized, or blue, phase. This allows all interproximal and occlusal adjustments to be completed before final crystallization and glazing.

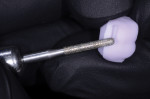

The kit has four basic components: a medium-grit pink grinder wheel, a flat-end parallel medium grit, a round-end parallel medium grit, and a pointed or needle-shaped medium grit.

The pink grinder wheel (LD15MD) is a great tool for quick sprue removal or interproximal adjustments. It allows controlled and efficient adjustments that leave the surface texture smooth and ready for any needed characterization or glazing. This wheel can also be used on areas that may require major adjustments. Whether you need to contour the buccal, lingual, or interproximal contact areas, or even the underside of a bridge pontic, this wheel is up for the task (Figure 1).

The round-ended parallel medium-grit diamond bur (842R.11.018) is the second bur in the kit. The parallel cylinder portion can be used for gross removal of the sprue and then the rounded tip can be used for final blending and contouring of the sprue attachment. The rounded portion is useful in adding slight texture to the facial and lingual surfaces of anterior restorations prior to firing as well as any needed occlusal adjustments in the anterior or posterior before firing or crystallizing (Figure 2).

The flat-ended parallel medium-grit diamond bur (842.11.018) also works great for sprue removal. By using the parallel long side of the bur, the sprue can be removed efficiently and the surface contour established. Interproximal adjustments and contouring can be accomplished with the bur’s long parallel surfaces. By turning the bur to use the transition angle from the side to the flat tip, primary anatomy can be added as needed or can be enhanced. Be certain to understand the thickness limitations. Before enhancing or adding anatomy in a crown or bridge, keep this recommendation in mind so that you can avoid thinning the restoration too much: A minimum thickness of 1.5 mm should be maintained throughout the central fissure of all posterior restorations (Figure 3 through Figure 6).

The final bur in the kit, the pointed or needle medium-grit diamond bur (859.11.018), also has multiple uses (Figure 7). The thin tip is ideal for fine adjustments around the margins. The primary use for this bur is connector contouring on anterior and posterior fixed partial dentures (bridges). The connectors are the most important factor in the overall success of an e.max bridge. If not adjusted properly (bur too course or too much heat generated), microcracks can form and lead to failure under load and function. This bur is ideal for contouring the connectors while maintaining structural integrity. Ivoclar recommends connectors to be a minimum of 16 mm2. Before beginning the adjustment, be aware of the starting dimension of any bridge connector. After adding depth and detail, the connector can be characterized with stains (Figure 8 and Figure 9).

The versatility of IPS e.max has enabled CAD users to successfully and confidently restore almost any clinical situation chairside. We are now able to provide our patients with the highest quality, most esthetic, and durable chairside restorations in the history of CAD/CAM. Thanks to Brasseler and Ivoclar, finishing these restorations just got a whole lot easier.

Disclosure

David M. Juliani, DDS, has received speaker fees from Ivoclar Vivadent but was not compensated for this article.