Fabricating New Dentures From Existing Ones

Denture system’s design tools and monolithic material facilitate efficient, esthetic results

Rami Ammoun, DDS, MS, CDT

During the past decade, treatment modalities for managing edentulous patients have rapidly evolved with the introduction of new digital denture protocols, technologies, and materials. At one end of the spectrum, there is the conventional approach, which involves tedious and time-consuming clinical and laboratory procedures that can present challenges to the dental team's ability to deliver a highly functional and esthetic final removable prosthesis.1,2

At the other end of the spectrum, CAD/CAM approaches have greatly simplified and streamlined the procedures associated with denture fabrication.3 Whether fabricating a new denture, a reline, or a replacement prosthesis, the use of intraoral scanning, 3D printing, and milling technologies, as well as precision digital workflows and new innovative materials, can provide the dental team with an efficient method of producing strong, functional prostheses with esthetic results that equal or exceed those achieved by conventional fabrication methods.4,5

Case Report

A 76-year-old woman presented to the clinic with the chief complaint that her dentures no longer fit properly. She requested that a new set of dentures be made for her. Upon examination of her existing dentures, it was noted that the denture teeth and prosthetic bases clearly exhibited wear (Figure 1 and Figure 2). The patient also noted that she did not wish to have the gold design that was present on tooth No. 9 of her maxillary denture replicated for her new set of dentures (Figure 3).

First Appointment: Record Taking

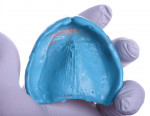

In the first step in this digital workflow, the patient's existing dentures are used as custom trays to make definitive impressions of both arches. For the mandibular definitive impression, a medium body regular set impression material (Aquasil®, Dentsply Sirona) was used (Figure 4). This high viscosity medium body material was chosen for the mandibular impression in order to best capture the lingual flanges. For the maxillary definitive impression, a light body impression material (Aquasil®, Dentsply Sirona) was used (Figure 5). This material was less viscous than the medium body impression material, which helped to completely seat the maxillary denture.

After the final impressions of both arches were completed, the next step in the workflow was to digitally capture the cameo surfaces of both of the existing dentures as well as the intaglio surfaces of the analog impressions of both arches using an intraoral scanner (TRIOS® 4, 3Shape). A titanium spray was used on the surface of the maxillary denture impression to help facilitate the process and aid in more accurately capturing the deeper anterior regions. The existing dentures were then placed back into the patient's mouth with the impression material in place (Figure 6), and the intraoral scanner was used to digitally register the patient's bite and relate the upper and lower scans together (Figure 7).

CAD Protocol

To design the dentures and create a try-in prototype, the clinician imported the scan data into a CAD software program (3Shape Dental System 2020, 3Shape) with fully integrated, exclusive digital denture system workflows (Ivotion™ Denture System, Ivoclar Vivadent). The clinician chose to create the new dentures using this digital denture system because of its unique features and advantages as well as the strength of its materials. The system's innovative bicolor monolithic milling disc, which combines a premium denture base material with a proven, highly cross-linked PMMA denture tooth material, allows customized dentures with data-based three-dimensional teeth to be milled in a single operation from a single disc. This monolithic concept eliminates the denture tooth bonding process while allowing customization of the shape of the individual teeth for patient-specific dentures. Each denture arch can be milled in a single uninterrupted process and then finished and polished using a traditional rag wheel and pumice.

Once the dentures were designed using the software (Figure 8), CAM files were generated in STL format and exported to the 3D printer (Form 3B, Formlabs) for fabrication of the try-in set. The try-in dentures were then printed using a model resin (Model Resin, Formlabs).

Second Appointment: Try-In

After the patient arrived for her second dental office visit, her existing dentures were removed, and the printed try-in dentures were seated intraorally (Figure 9). The chosen occlusal scheme involved lingualized occlusion.7 The patient reported a comfortable and even bite with her try-ins. Although she was pleased with the fit and function of the new dentures, the patient stated that she would like more of her teeth and less gingival tissue to show in the maxillary denture when she smiles.

Final Design and Milling

Following modification of the design to meet the esthetic expectations of the patient, the CAM files for the definitive dentures were created and exported to the milling machine (PrograMill® PM7, Ivoclar Vivadent), and the denture arches were fabricated using the denture system's single uninterrupted manufacturing process.

Once the milling process was completed, a diamond disc was used to open the incisal and occlusal embrasures on the dentures to enhance their natural appearance (Figure 10). A composite material (SR Nexco®, Ivoclar Vivadent) was then used to add characterization to the anterior region of the maxillary denture (Figure 11), and a final layer of glaze (Optiglaze™, GC) was added to the cameo surfaces of both dentures to provide a nice polish.

Third Appointment: Final Seating

When the patient returned for her third and final office appointment, her new definitive dentures were inserted for assessment. Virtually no adjustments were needed to the occlusion or intaglio surfaces. The support and retention were excellent, and the patient expressed that she was very happy with the functional and esthetic results (Figure 12).

About the Author

Rami Ammoun, DDS, MS, CDT

Fellow

American College of Prosthodontists

Director of Digital DentistryTechnologies

Assistant Professor

Virginia Commonwealth University

Richmond, Virginia

References

1. Burt DA. Digital dentures: a paradigm shift in analog dentistry. Inside Dentistry. 2017;13(2):40-48.

2. Janeva NM, Kovacevska G, Elencevski S, et al. Advantages of CAD/CAM versus conventional complete dentures - a review. Open Access Maced J Med Sci. 2018;6(8):1498-1502.

3. Infante L, Yilmaz B, McGlumphy E, Finger I. Fabricating complete dentures with CAD/CAM technology. J Prosthet Dent. 2014;111(5):351-355.

4. Russo LL, Salamini A. Removable complete digital dentures: a workflow that integrates open technologies. J Prosthet Dent. 2018;119(5):727-732.

5. D'Arienzo, LF, Casucci A, Manneh P, et al. Digital workflow in complete dentures: a narrative review. Journal of Osseointegration, 2021;12(4);743-750.

6. Ammoun R, Bencharit S. Creating a digital duplicate denture file using a desktop scanner and an open-source software program: A dental technique. Journal of Prosthetic Dentistry. 2020;125(3):402-406.

7. Abdou J. Occlusal schemes for complete dentures: a systematic review. Int J Prosthodont. 2013;26(1):26-33.