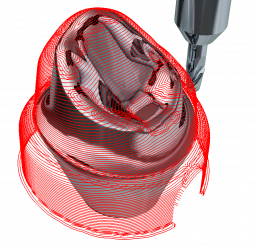

Built upon the industry leading PowerMILL solution, DentMILL enables you to machine single or multi-unit copings, crowns and bridges as well as abutments, bars and screw retained bridges in a wide range of materials including zirconium, PPMA and wax.

Delcam’s DentMILL encompasses fully automated manufacturing methods that reduce costs, and improve quality and productivity. It offers the latest parallel processing technologies so your team can add and process new jobs while tool paths are generated in the background. It removes unnecessary downtime by allowing multiple jobs and blocks to be processed simultaneously.

Intelligent workflow ensures that only machines, fixtures, materials and suitable machining strategies can be selected by the operator. Since it is an open CAM system, design form other CAD packages can be imported so tool paths can be generated on simple or complex restorations created by any CAD system. Stock management ensures you are only selecting blocks for which you have physical stock.

The rapid nesting algorithm allows you to fill and pin a block quickly and efficiently. DentMILL’s part-to-part pinning allows you to get the maximum yield from your blocks.

An automation layer allows operations in a lights-out milling facility as part of an integrated CAD/CAM workflow or stand-alone piece. DentMILL allows you to build machine and fixture libraries to match available equipment, this integration speeds up DentMILL’s CAD/CAM workflow by removing expensive data administration time.

DentMILL is flexible scalable, and available in three levels:

- DentMILL - for 3+1 axis and single implant machining

- DentMILL Plus - adds 3+2 axis machining and part tilting

- DentMILL Pro - adds full 5 axis machining and support for milling all multi implant restorations

DentMILL is linked to Delcam’s OrderManager workflow management software so that the new part library is updated automatically once a new order is received. OrderManager then manages the whole process from the initial order through to manufacturing and final dispatch. At all stages users can maintain a ‘real-time’ view of the centre’s total order status.

The improvements in the 2014 R2 release provide a quicker, slicker and more intelligent mechanism for transferring new restorations into DentMILL from OrderManager thus making the whole process more efficient and saving time.

DentMILL 2014 R2 gives users more control when using the multi-holder fixture. For example, if similar types of restoration are being produced in all the positions, the same set of strategies can be applied to the complete group. Alternatively, individual machining approaches can be used to calculate the toolpaths if each item is of a different type.

In addition, the machining sequence can be set up so that all operations with a particular tool across the various items can be completed in sequence before moving to the next cutter so reducing tooling changes. If preferred, each restoration can be machined completely before moving to the next item.

The option to scale models to compensate has been made more powerful with the ability to undertake non-uniform 3D scaling, allowing more accurate scaling to give better-fitting restorations.

Data import has also been enhanced to improve the import of models from many different open and closed systems, an important area for an open system like DentMILL. In particular, more variants of 3Shape parts can now be read into the software.