Selecting Luting Agents

Make the choice based on the evidence as well as physical properties.

Luting agents provide the final step in a sequence of precise procedures culminating in the delivery of the definitive prosthesis. Long-term success depends on proper selection and appropriate manipulation of the luting agent. Although it is important to choose the best luting agent for each clinical situation, far greater variations in physical properties occur for improper manipulation of a given luting agent than exist between different types of cements.

The ever-evolving science of adhesion to tooth structure has created numerous, chemically different formulations of luting agents. This has created confusion for many dentists about the type of luting agent to use in different clinical situations. In many circumstances, resin-based cements are considered the panacea for poorly designed indirect restorations and have been overused.

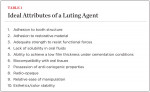

The ideal attributes of a luting agent are listed in Table 1. Luting agents can be classified into three categories based on their type of union with tooth structure. These are non-adhesive, chemical bonding, and adhesive (Table 2).

Zinc phosphate, glass ionomer, and polycarboxylate cements have a long history of use and are the gold standards against which other cements are compared. This article will review the characteristics of the contemporary luting agents. They include resin-modified glass-ionomer (RMGI) cements, dual-cured resin cement (DC), conventional cement (CC), and light-cured composite resin (LC).

Clinical Recommendations

There is no ideal luting agent for all procedures; the choice should depend on physical properties, technique sensitivity, and the evidence. The type of restoration being fabricated also has an important role in the selection of a luting agent, with the requirements of bonded restorations being very different from those of cast restorations. Physical properties of a luting agent, although somewhat important, cannot be used as the sole basis for selecting a cement (Table 3). Two criteria to consider would be evidence and technique sensitivity. It is reasonable to assume that unless a specific indication for a given luting agent exists, the least technique-sensitive material should be used.

Resin-Modified Glass-Ionomer Cements

Resin-modified glass-ionomer (RMGI) cements are regarded as dual-cured materials, setting by an acid-base reaction and polymerization. Many papers cite fluoride release and decrease in solubility as advantages; however, these have not shown to be clinically significant. Advantages do include decreased technique sensitivity. To avoid inconsistencies in the mix and maximize the cement properties, automix capsules should be selected over powder/liquid presentations. The clinical efficacy of these cements has been confirmed in the scientific literature.

RMGI cements are the most frequently used cements in North America for the cementation of well-fitting porcelain-fused-to-metal crowns, full-cast crowns, and high-strength (eg, zirconia, alumina) ceramic restorations. Examples of RMGI cements would include GC America’s FujiCEM™ Automix and GC Fuji PLUS™ (GC America www.gcamerica.com) and 3M ESPE’s RelyX™ Luting Plus and Photac™ Fil (3M ESPE, www.3mespe.com).

Resin Cements

Resin cements are the most versatile and widely used cements for non-metallic restorations, resin-bonded fixed partial dentures, ceramic crowns that can be etched, and porcelain veneers, as well as ceramic and resin composite inlays and onlays.

All-Ceramic Crowns

Luting of all ceramic crowns is dependent on the substrate being used (Table 4). Ceramic restorations available today are either etchable or non-etchable based on the core material. Etchable are the silica-based ceramics: feldspathic, leucite-reinforced, and glass ceramics. Non-etchable are the non-silica–based ceramics, such as aluminum oxide and zirconium oxide.

Conventional Ceramic— Etchable Materials

Feldspathic Ceramic

Due to their exceptional esthetic properties, clinicians often choose silica-based ceramics, such as feldspathic porcelain and glass ceramic for veneering the metal frameworks or high-strength ceramic copings of their all-ceramic restorations. Although the feldspathic ceramic is brittle with low flexural strength by itself, modern adhesive cementation with composite increases the fracture resistance of the ceramic.

Reinforced Conventional Ceramic

Leucite-reinforced feldspathic porcelain—eg, IPS Empress® from Ivoclar Vivadent, (www.ivoclarvivadent.com)—achieves significantly higher fracture strength and can be used to fabricate partial or full-coverage all-ceramic restorations if resin bonding techniques are properly applied. Its success on anterior teeth is superior to that on posterior teeth.

A lithium-disilicate glass-ceramic core veneered with a sintered glass-ceramic—eg, IPS e-max® from Ivoclar Vivadent—offers further strength, which the manufacturer claims allows for the fabrication of short-span fixed partial dentures. Although several manufacturers have marketed their systems as suitable for the fabrication of all-ceramic fixed partial dentures, no long-term clinical trials have verified their efficacy, and further, many anecdotal reports of early failure exist.

When luting lithium disilicate restorations, the dentist has a choice to adhesively bond or conventionally cement the restorations. When bonding, a 5% HFL gel is applied to the intaglio of the restoration for 20 seconds and then copiously rinsed with water. A primer is applied for 60 seconds. This primer allows bonding of the resin-based cement to the restorative material. Depending on the type of luting agent used (self-etch adhesive resin/adhesive resin) the tooth may or may not need to be pre-conditioned. It is critical to follow the manufacturer’s recommendations when luting these restorations.

Cementation of Conventional Ceramic

The ceramic surface should be etched with 4% to 10% hydrofluoric acid for 1 to 3 minutes. After etching, the ceramic should be rinsed copiously with water. After etching, ceramic residues often form on the fitting surface of the ceramic. These ceramic residues can compromise the bond strength of the ceramic to the composite. The ceramic restoration should be placed in an ultrasonic bath in distilled water for 4 minutes. After cleaning, the ceramic surface should be evaluated to confirm the absence of residues. One coat of adhesive resin should be applied to the fitting surface of the restoration after silane application, and the restoration should be stored under a light shield to prevent premature curing of adhesive resin.

Two types of luting agent are used for conventional ceramic materials. These are dual-cured (DC) and light-cured (LC) resin cement. LC cements have some proven advantages in that working time is increased, the ability to remove excess cement is facilitated, and this reduces finishing time. DC cements traditionally are used when ceramic thickness does not allow light penetration for maximal conversion of the luting cement. With thick ceramics, LC cements do not reach a level of microhardness of maximum cure. Disadvantages of DC cements include porosity from mixing, reduced working time, decreased degree of conversion, and color instability due to amine degradation.

High-Strength Ceramic—Non-Etchable

Glass-Infiltrated Aluminum-Oxide Ceramic

With the increase of aluminum oxide content in feldspathic ceramics, there has been a significant improvement in the mechanical properties (eg, flexural strength of 450 MPa) of In-Ceram® Alumina (Vident, www.vident.com), allowing metal-free restorations to be used more predictably. Due to the low silica content, acid etchants used for conventional ceramics do not sufficiently roughen the surface of aluminum-oxide ceramics. Airborne particle abrasion with aluminum oxide is effective to roughen this ceramic surface. The application of silica coating on this ceramic also has been recommended.

Densely Sintered Aluminum-Oxide Ceramic

Procera® AllCeram (Nobel Biocare, www.nobelbiocare.com) is a high-strength ceramic material (flexural strength of 610 MPa) with a highly dense, sintered aluminum oxide content (99.9%) with a negligible glassy phase. Procera AllCeram crowns have proved to be a reliable choice for the restoration of anterior teeth on both natural and implant-supported abutments. Tribochemical silica coating systems increase the tensile bond strength values between Panavia™ F (Kuraray Dental, www.kuraray-dental.com) and Procera AllCeram ceramic. Sandblasting alters the surface of densely sintered alumina more effectively for increased bond strengths than do conventional acid-etching and grinding. For superior retention of alumina-reinforced ceramic systems, a retentive preparation design is recommended. Clinical studies suggest that for such restorations, resin cement and hybrid glass-ionomer cement1-3 may be appropriate luting agents.

Zirconium-Oxide Ceramic

The clinical use of zirconium oxide as a core material has advantages, including a high flexural strength of over 1,000 MPa. Polycrystalline zirconium oxide is typically used in a tetragonal crystalline phase, partially stabilized with yttrium oxide. A unique property is the so-called ‘‘transformation toughening,’’ where a partially stabilized zirconium oxide can actively resist crack propagation through a transformation from a tetragonal to a monoclinic phase at the tip of a crack, which is accompanied by a volume increase. Due to their high strength, zirconium-oxide ceramics are considered for use in numerous restorative procedures, including implant abutments and full-coverage crowns.

Cementation of High-Strength Ceramic

As such high-strength ceramics are not etchable, predictable long-term success requires retentive preparations and alternative surface treatments. At present, the studies on air abrasion of zirconia are not conclusive and the optimal preparation protocol has not been delineated. Assuming a retentive preparation, the optimum luting agent with the least technique sensitivity would be resin-modified glass-ionomer cement. Alternative luting agents for these restorations include phosphate-monomer–containing resin cement, conventional resin cement, resin-modified glass-ionomer cement, glass-ionomer cement, or zinc-phosphate cement. Recently, self-etching, adhesive cements (eg, Maxcem®, Kerr Sybron Dental Specialties, kerrdental.com; Rely-X™ Unicem, 3M ESPE; Universal Resin Cement, Pulpdent Corporation, www.pulpdent.com) have been developed. There are several in vitro studies showing their effectiveness, but there is no long-term clinical study available and their adhesive properties have not been investigated completely yet. The clinical success of high-strength ceramic restoration does not rely on the resin bond to the crown, even though some authors have concluded that, based on the current evidence, adhesive cementation procedures are necessary to support all-ceramic materials.

Conclusion

As there is not yet a single luting agent that can completely make up for deficient preparation retention and resistance form or ill-fitting, low-strength restorations, clinicians should take into account the advantages and disadvantages of each luting agent to make an appropriate selection (Table 5).

References

1. Donovan TE, Cho GC. Contemporary evaluation of dental cements. Compend Contin Educ Dent. 1999;20(3):197-210.

2. Jivraj SA, Kim TH, Donovan TE. Selection of luting agents, part 1. J Calif Dent Assoc. 2006;34(2):149-160.

3. Kim TH, Jivraj SA, Donovan TE. Selection of luting Agents, part 2. J Calif Dent Assoc. 2006;34(2):161-166.

About the Authors

Sajid A. Jivraj, DDS, MS Ed

Private Practice

Oxnard, California

Mamaly Reshad, DDS, MSc

Private Practice

Los Angeles, California

Terry Donovan, DDS

Professor and Section Head of Biomaterials

Department of Operative Dentistry

University of North Carolina

School of Dentistry

Chapel Hill, North Carolina