Don't miss a digital issue! Renew/subscribe for FREE today.

×

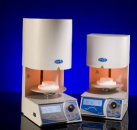

Furnaces

Whether sintering zirconia or pressing porcelain, a furnace can make or break a restoration. Specific requirements must be adhered to in order to get the best results from the various materials on the market, so it is important to have a furnace that works well in your laboratory’s workflow. Make this product page your resource for the latest furnaces of all kinds.