Why Argue?

Communication can strengthen the dentist/technician relationship

By Tom Fuschetto, DDS, and Vincent Verderosa, MDT, CDT

When the dentist co-author, a former dental technician, was in his fourth year of dental school, he realized that communication between a dentist and technician was not stressed enough or really taught. He'd overheard other students making statements such as "the lab messed it up," "they don't listen," and even "that lab doesn't know what they are doing." Hearing these sorts of negative comments concerned him, mainly because it was setting up these future clinicians for failure with regard to their relationships with their laboratories. Taking this to heart, he decided to document a denture patient from start to finish and show how communication could prevent pitfalls in what can be seen as a routine treatment. He sought the assistance of the dental school's laboratory technician, co-author Vincent Verderosa, MDT, CDT, who helped to demonstrate how proper communication results in good and predictable patient outcomes and develops a great working relationship with the laboratory technician.

There are three forms of communication between a dentist and laboratory technician: written, oral, and visual. Most of the time, the only communication is written, which can be sufficient for something simple. However, utilizing all three communication forms truly increases the chances of a successful outcome. In the treatment described, written prescriptions, oral communication (either face-to-face or over the phone), and digital photography were all utilized to achieve the final result.

Treatment

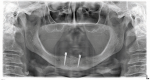

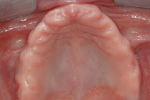

The patient presented to the Stony Brook University School of Dental Medicine Dental Care Center seeking replacements for her maxillary complete denture and mandibular implant-retained overdenture (Figure 1 through Figure 4). She was not happy with her previous prostheses—not with their fit, function, or esthetics. After performing a thorough evaluation of both the patient and her dentures, the dentist determined that there was a good prognosis for successful treatment.

At the first visit, properly extended maxillary and mandibular alginate impressions were made and diagnostic casts were developed. After casting the impressions in Type III dental stone and trimming, the dentist drew the outline of where he wanted the custom trays to end. This was 2 mm to 3 mm short of the vestibule. The dentist also marked the location of the tissue stops. He then requested the laboratory technician to fabricate maxillary and mandibular custom trays based on the drawings provided on the casts, using one layer of baseplate wax as a spacer. At that point, the dentist also wrote specific instructions to block out the area over the LOCATOR abutments (Zest Dental Solutions; zestdent.com) to allow room for the height of the impression copings, and included the impression copings with the diagnostic casts for reference.

In the laboratory, the technician evaluated the diagnostic casts for undercuts and appropriately blocked them out using baseplate wax. Next, a sheet of baseplate wax was softened, molded to the diagnostic casts, and trimmed to the drawn line. For the mandible, 5-mm high cylinders of wax were added over the location of the LOCATOR abutments to allow room for the impression copings. When appropriately adapted, four tissue stops were cut into the wax in the approximate locations that were marked. Triad Model Release Agent (Dentsply Sirona; dentsplysirona.com) was applied to the wax and Triad Custom Tray material (Dentsply Sirona) was adapted and trimmed to the appropriate lines. The excess material was used to fabricate handles. The trays were placed in the Triad 2000 light curing unit (Dentsply Sirona) for 2 minutes, carefully removed from the casts, and then the intaglio was polymerized for another 5 minutes in the curing unit. Once polymerization was complete, the trays were cleaned with ethanol-soaked gauze to remove any of the residual model-releasing agent and trimmed with a bur until the edges were smooth. The custom impression trays were then checked on the diagnostic casts for appropriate extension and ease of draw and returned to the clinician.

Custom trays were returned properly extended to the outline on the casts, thus providing a good starting point for the border molding and final impression procedure. During the following appointment, the custom trays were seated intraorally and relieved accordingly to allow sufficient room for border molding compound. Border molding was completed using green stick Impression Compound (Kerr Dental; kerrdental.com), PVS adhesive was applied to the trays, and final impressions were made using Aquasil LV Fast Set PVS impression material (Dentsply Sirona). As for the mandibular overdenture impression, the LOCATOR impression copings were seated on the LOCATOR abutments prior to making the mandibular impression.

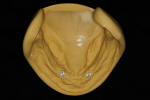

Once the final impressions were obtained, they were disinfected in accordance with clinical protocol and sent to the laboratory. The laboratory technician boxed, beaded, and cast both final impressions in vacuum-mixed Type III dental stone with specifications to properly seat the LOCATOR replicas prior to master cast fabrication. After the master casts were trimmed (Figure 5 and Figure 6), a chrome-cobalt mesh framework was prescribed to be fabricated for the mandibular overdenture, according to the drawing on the diagnostic cast (Figure 7). The mandibular master cast was blocked out and duplicated with reversible hydrocolloid; then, the mesh framework waxed on the duplicated cast, invested, cast in chrome-cobalt, finished, and polished. The laboratory technician agreed to the dentist's suggestion to attach the LOCATOR housings onto the framework using autopolymerizing acrylic resin. The LOCATOR housings were then luted to the cast chrome-cobalt frame with Nature-Cryl (GC America Inc.; gcamerica.com) and baseplate wax was added to the dimensions of an occlusal rim (Figure 8). The maxillary cast was appropriately blocked out with baseplate wax and the record base was fabricated using Triad Denture Base material (Dentsply Sirona). Baseplate wax was then added to the appropriate dimensions of the maxillary wax rim (Figure 9).

The maxillary rim was adjusted first to level the horizontal plane, followed by creating the appropriate Camper's plane and building out the appropriate facial contours. This step is the most important because it communicates to the laboratory technician where the dentist wants the incisal edges and buccal cusps to be placed. Once the maxillary wax rim was finalized, the mandibular wax rim was inserted and the appropriate vertical dimension of occlusion was established. The maxillary and mandibular dynamic midlines were then marked, along the canine eminences and high smile line, and the interocclusal centric relation registration was recorded using Blu-Mousse (Parkell Inc.; parkell.com). At this point, the patient was photographed to communicate with the laboratory technician the contours created with the wax rims and the patient's midline (Figure 10). Based on the patient's facial characteristics and width of her ala, the depicted SR Phonares II artificial teeth (Ivoclar Vivadent; ivoclarvivadent.com) were selected. Upon discussion with the dentist, the laboratory technician articulated the master casts (Figure 11) and set the maxillary and mandibular teeth up to the first bicuspid to evaluate the esthetics at the next visit.

In the laboratory, the technician followed the wax rim profile and viewed digital photographs of the wax rims in the patient's mouth to appropriately position the maxillary anterior teeth. The mandibular anterior teeth were set so that 1 mm of vertical and horizontal overlap was present. Generally, the first artificial tooth assessment appointment allows the clinician to fine-tune the anterior esthetics and confirm the articulation of the master casts. In this treatment, the anterior teeth were lengthened slightly, the articulation was confirmed, protrusive interocclusal record was made, and the condylar inclination was set. The patient and the dentist were happy with the esthetics, so the dentist photographed the patient's smile to show to the laboratory technician. At this point, he instructed the laboratory technician to set the posterior teeth in a lingualized first molar occlusal scheme and return for final wax try-in. In the laboratory, the technician first set the mandibular posterior teeth over the center of the alveolar ridge to the level of two-thirds up the retromolar pad. Both the medio-lateral and antero-posterior compensating curves were created. The maxillary posterior teeth were then set so that the lingual cusp contacted the central fossa of the mandibular posterior teeth. Both working and balancing occlusal contacts were created, and the arrangement was waxed to the appropriate gingival heights and sent to the clinician to try in. During the second try-in appointment, the patient's occlusion and esthetics were confirmed to the clinician and patient's liking, and photographs of the final arrangement were made to further communicate with the laboratory technician (Figure 12 and Figure 13). Also, at this visit the posterior palatal seal was marked intraorally using an indelible marker and transferred to the maxillary wax rim. Once transferred, the area of the wax rim marked by the indelible marker was removed so that the posterior palatal seal could be accurately scribed on the master cast. The clinician scribed the posterior palatal seal into the master cast using a round bur and a discoid-cleoid carver.

The final artificial tooth arrangement was sent to the laboratory with the directions to wax down, seal, festoon, process in Lucitone 199 acrylic (Dentsply Sirona), and perform laboratory remount/equilibration. In the laboratory, the technician sealed the approved artificial tooth arrangement to the master casts and fine-tuned the festooning (Figure 14 through Figure 16). The master casts were removed from the articulator mounting plates and set in the denture flasks with plaster. To preserve the wax contours and prevent stone from sticking to the denture surface, a thin layer of high-impact laboratory putty (GC America Inc.), was applied to the buccal/occlusal/lingual surfaces of the wax set-up. (It is important to note that the cusp tips of the denture teeth must show through the putty to allow Type III dental stone to provide a positive seat that has minimal deformation.) After the putty set, the dental stone was flowed into the flask and the flask was closed. When the dentures were invested and wax elimination was complete (Figure 17 and Figure 18), the dentist had a conversation with the laboratory technician about whether or not the LOCATOR housings were to be processed in the laboratory. Based on the conversation, which also included attending faculty from the dentist's dental school, it was decided that the housings would be attached intraorally. The intaglio of the denture would be relieved around the LOCATOR abutments. After wax elimination, Al-Cote Separating Agent (Dentsply Sirona) was applied to the stone surfaces, the teeth were removed from the flask, air-particle abraded on the surfaces contacting the denture base, steam cleaned, and placed back into the flask. Lucitone 199 heat-polymerized acrylic was mixed, the teeth were coated with monomer to help create a chemical bond, and the acrylic was packed into the denture flask when it was in its doughy state. For the maxillary denture, three trial packs were completed at 1500 psi prior to final-closing the flask at 3500 psi. Only one pack was utilized for the mandibular overdenture at 3500 psi; this was due to the presence of the mesh framework that was attached with LOCATOR attachments to the cast. After curing for 10 hours, the dentures were divested, a laboratory remount was performed, and the dentures were trimmed and polished using pumice and Acrilustre (Buffalo Dental Manufacturing Co. Inc.; buffalodental.com). The LOCATOR attachments were removed from the mandibular overdenture and returned to the clinician.

At the following visit, the dentures were delivered. To increase retention of the mandibular overdenture, COE-SOFT (GC America Inc.) softliner was added to the relieved areas where the future LOCATOR housing would be attached (Figure 19). After two weeks and two denture adjustments, the LOCATOR housings were air-particle abraded, coated with metal primer, and attached to the mandibular overdenture using Pattern Resin (GC America Inc.) and the least retentive blue male attachments were placed in the housings (Figure 20 and Figure 21). By the end of the treatment, the patient was extremely happy with the esthetics, phonetics, occlusion, and retention of her new set of dentures (Figure 22 through Figure 28).

Conclusion

Throughout this patient treatment, there were several opportunities for a communication breakdown. However, the use of thorough written prescriptions, properly executed clinical steps, in-person conversations, and photography ensured clear instruction and expectations. In addition to communication, the relationship between dentist and technician should be one of utmost respect for both parties to allow for critiques and suggestions for improvement on both ends. In the dentist's career as a laboratory technician, dental student, and prosthodontic resident, the strength of the dentist-technician relationship has been the driving factor for communication with the dental laboratory, and has proven itself with successful and predictable patient treatment outcomes.

About the Authors

Tom Fuschetto, DDS

Prosthodontic Resident

Department of Prosthodontics and Digital Technology

Stony Brook School of Dental Medicine

Stony Brook, NY

Vincent Verderosa, MDT, CDT

Senior Laboratory Technician

Department of Prosthodontics and Digital Technology

Stony Brook School of Dental Medicine

Stony Brook, NY