Smart Shopping

Major factors to consider before making a CAM milling machine purchase.

By Chris Brown, BSEE

Dental CAD/CAM milling systems come in all shapes, sizes, and configurations. Open or closed architecture, single stock or multi-unit feed, dry or wet mill, three-axis or five-axis—these are just a few factors laboratory professionals must weigh before making a purchasing decision. So how do laboratory owners choose a configuration that best fits their business model and what features are important to a typical dental laboratory?

CAM Architecture

One of the hottest discussion topics surrounding dental CAD/CAM is closed versus open architecture. It is one of the first things that needs to be considered when researching CAM milling systems. Is open better than closed? The answer boils down to a combination of personal preferences and business direction.

Closed architecture offers laboratory owners security and a one-stop shop for resolving problems. One company controls both the CAD and CAM configurations, knows the milling unit’s performance specifications and capabilities, and is able to adapt the CAD and CAM software accordingly. For those who are somewhat technology-phobic, but ready to take the plunge, closed architecture systems generally do a great job of taking the user by the hand from start to finish. The production process from scan to design to milling is made easy.

Open architecture offers flexibility and choice. It allows users to work with CAD designs from any other “open” system and to choose which CAD system they prefer. An increasing number of CAD design software systems and digital intraoral impression scanners feed into open architecture CAD software programs. For optimal results, CAD operators may have to adjust certain settings within their software to match the milling system’s capabilities. For those who are unafraid to customize their own settings or configurations, open architecture offers a wider array of business options, such as the potential to become an outsourcing partner for other laboratories or to integrate new interfaces with emerging CAD software platforms.

CAM Software

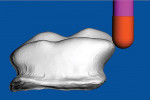

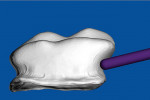

Every milling system must have CAM software to make it work. CAM software assesses the parts to be milled then figures out the best way to cut those parts from the available stock material. It generates a program that tells the milling unit which bur to use, in which order, and which milling path to follow (Figure 1).

CAM software must be programmed with the available burs, their shapes, lengths, and diameters. It must also be configured with information on how fast the burs can spin, how fast they can move through the material, and how much material they can cut with each path.

With most open-architecture systems, the CAM software is usually completely separate from the CAD software. On most closed-architecture systems, CAM software is often integrated with the design software.

How does the CAM software fit into a CAM milling unit purchasing decision? Usually, the consumer does not have a choice. Given the amount of mill-specific information programmed into the CAM software, most milling system manufacturers have partnered with a single CAM software supplier. However, CAM software programs do have differences that should be explored before making a purchasing decision. For example, the ease of selecting and placing parts to be milled within the stock material can vary. Some programs have special software tools to manipulate part position or to place additional support structures on the parts. The speed at which tool-path calculations are performed can vary as well. The good news is that most CAM software does an excellent job, as mill manufacturers have worked closely with CAM software suppliers to optimize the programs for their mills.

Three-Axis vs. Five-Axis

A three-axis mill allows the stock material or the cutter to move in three axes. For example, the stock may be held in a fixture that moves left and right (first axis) and front to back (second axis), with a spindle that moves up and down (third axis). Another three-axis mill might hold the stock in one position, with the spindle moving left to right, front to back, and up and down (all three axes).

With a three-axis mill, it is easy to imagine creating the occlusal surface of a restoration as the mill moves in all three axes, but how is the other side of the restoration milled? In most cases, the fixture holding the stock flips over, and the mill moves or cuts again in three directions. This is actually known as a “3+1” axis configuration. A three-axis mill essentially cuts from the top and bottom of the restoration, parallel to the path of insertion. It is not capable of milling undercuts (Figure 2).

There are two types of five-axis mills—the “3+2” and the continuous five-axis. In the “3+2” configuration, the mill operates similarly to a three-axis mill with three directions of movement and cutting. However, then without cutting, either the stock material or the spindle can be moved and held in a position not parallel to the path of insertion ( Figure 3). Once re-positioned, the mill can again move and cut with three axes of motion. In a continuous five-axis configuration, the mill is capable of constantly re-orienting the stock or the spindle off the path of insertion while simultaneously cutting and moving in the other three axes.

Five-axis milling has many potential advantages. It can provide longer tool life by angling the cutting surface and using the sides of the bur instead of just the tip, and it can produce improved surface finish for the same reasons. Additionally, shorter cutting tools can be used to minimize tool wobble and improve stability and overall accuracy. Because five-axis milling can cut from the side, it can mill undercuts and parts can be tilted off the path of insertion to allow the use of shorter stock material.

So is three-axis or five-axis better for dental laboratories? For most crown and bridge cases, three-axis milling is adequate. There is typically a $20,000 premium to add the fifth axis. A laboratory would have to mill a lot of undercuts and tall bridges with off-axis insertion angles to pay back that kind of investment. The other potential benefits of five-axis milling are subject to how well the CAM software is configured and the quality of the spindle/motor controller. Laboratory owners looking to mill high volumes of custom implant abutments or implant-retained structures should be looking at five-axis mills. However, some of the consequences of five-axis milling include additional time during project calculations and milling and the consumption of additional stock material.

Dry vs. Wet Milling

Zirconia, wax, and PMMA are some of the most commonly milled “dry” materials. They can also be milled in a wet mill, but may be subject to a post-milling drying process. Lithium disilicate, titanium, chrome cobalt, and HIP zirconia, on the other hand, must be milled in a wet mill.

Dry mills create significant dust and require a vacuum system that needs to be maintained and emptied. Wet mills use a liquid to cool the cutting tools and wash away scrap materials, which means the liquid must be replaced and the filters must be cleaned (Figure 4). They also tend to be a little noisier because of the fluid pump. When deciding between a dry or wet system, laboratory owners should consider the type of materials they plan to mill and the type of maintenance they are willing to perform (Figure 5).

Single Stock vs. Multi-Stock Feeder

Most mills allow for a single piece of stock to be placed manually in the mill. In most cases, multiple units may be milled from that single piece of stock. However, there are also models that automatically feed additional stock to the mill to keep it running without user intervention (Figure 6).

Milling centers and high-volume milling laboratories can realize significant benefits from auto-feeders, while most small and mid-sized laboratories do not operate at volumes where an auto-feeder is necessary.

CAM Tooling

During the milling process, some mills use as few as two milling tools—others may use as many as five or six. Theoretically, more tools means better, more accurate milling and improved detail with fewer adjustments. However, CAM software programming and controller specifications can significantly impact the usefulness of the additional tools.

Most materials are milled with carbide tools. Lithium disilicate and other ceramic materials are better milled with diamond tools. Depending on the material being milled, tooling can add $3 to $6 cost to each restoration. Although potential buyers sometimes overlook this figure, it is an important consideration in determining the overall cost of a milling purchase.

Accuracy, Speeds, and Feeds

Milling system manufacturers often quote specifications for accuracy and axis travel speeds. While these are important numbers, they are more valuable to the person programming the CAM software for the mill. Even though the motors in the mill are capable of achieving those numbers, they will not necessarily achieve them in actual use. Parts moving at maximum speeds typically do not change directions as smoothly as they do at slower speeds. The CAM software programmer takes that into account, along with material and tool characteristics, to find the best compromise between speed and accuracy.

Bottom Line

Manufacturers today offer a wide selection of milling systems—from the smaller, low-volume tabletop units to automated, floor-mounted, high-production systems. Buyers should select open or closed architecture based on their technical inclination, customer base, and business model. Their choice between three- or five-axis milling will depend on the products they want to manufacture, while their decision about wet or dry milling will be based on the materials they want to work with. As for choosing between a single-stock or multi-stock feed, laboratory owners should estimate the volume of work they anticipate in their laboratories.

Regardless of the milling system purchased, potential buyers should calculate whether it can pay for itself in 18 months or less. Technology is moving fast; if a capital investment cannot produce a return on investment within that timeframe, chances are the laboratory will be looking to upgrade to the latest model while still making payments on the old mill.

About the Author

Chris Brown, BSEE, is the business manager of Apex Dental Milling in Ann Arbor, Michigan.