The focus of the development was clearly on the issue of safety, as only durable restorations are of benefit to the laboratory, the clinician and the patient. For this reason, numerous studies were already conducted by renowned external institutes during the development phase. The result was conclusive: the fast sintering cycle has no relevant influence on optical or mechanical properties. In addition, the high flexural strength of > 800 MPa and the associated classification as a Class 5 zirconia provides an additional safety cushion.

Both laboratories and dental practices benefit from this innovative high-speed sintering process enabling them to add the so-called "Same Day Crown" to their service offering. Due to the extremely shortened sintering process, single-tooth crowns and three-pontic bridges can be realized in just one day, from preparation to final insertion.

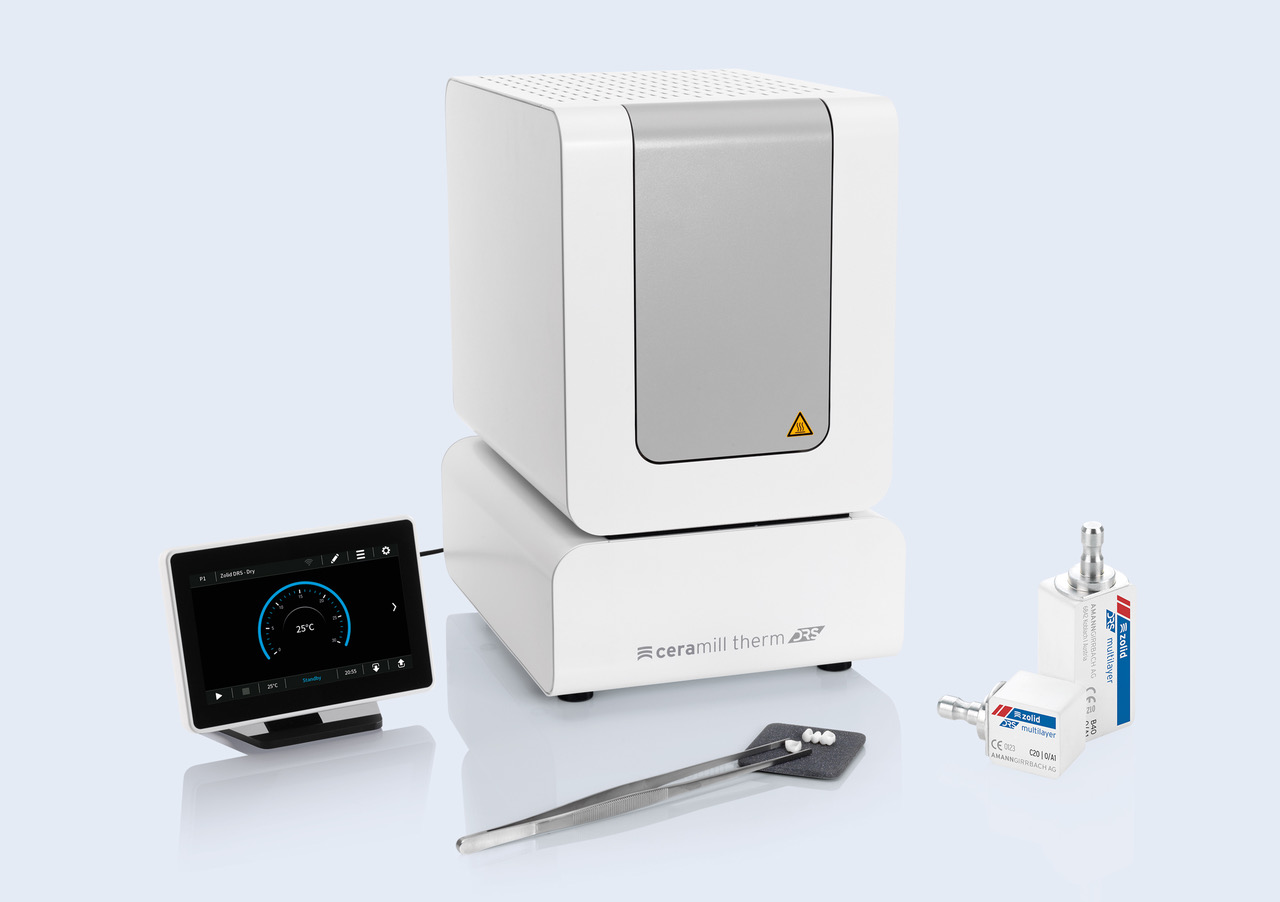

What's more, the fabrication of other indications can also be shortened considerably, for example, an implant restoration consisting of a zirconia abutment and a crown. Whereas previously at least two days had to be allowed for in planning, this type of restoration, it can now be fabricated easily in less than 24 hours with the High-Speed Zirconia Kit.

The High-Speed Zirconia Kit offers every user an efficient and profitable process extension for the fabrication of zirconia in everyday routines - while at the same time maintaining natural esthetics and maximum safety.

About Amann Girrbach

As a pioneer in dental CAD/CAM technology, Amann Girrbach is one of the leading innovators and preferred full-service providers in digital dental prosthetics. With its high degree of expertise in development and commitment to customer orientation, the ambitious Austrian company creates sophisticated system solutions and highest quality materials for tomorrow's workflows. Its custom-ers in around 90 countries worldwide are mainly made up of dental laboratories and dental technicians. Amann Girrbach employs a total of around 500 people. In addition to the R&D and production sites in Koblach (headquarters) and Rankweil (Austria), Amann Girrbach operates sales offices in Pforzheim (Germany), Verona (Italy), Jossigny (France), Charlotte (USA), Singapore (city), Curitiba (Brazil) and Beijing (China).