Wixom, MI - Axsys Dental Solutions has expanded its line of dental machining centers with the addition of the new Versamill 5X200.

The 5X200 replaces the existing Versamill 5x and features a spacing-saving upright configuration with the same high-quality, vibration-dampening construction characteristics found in the Versamill 5x and many full-framed high-speed industrial CNC Machine Tools.

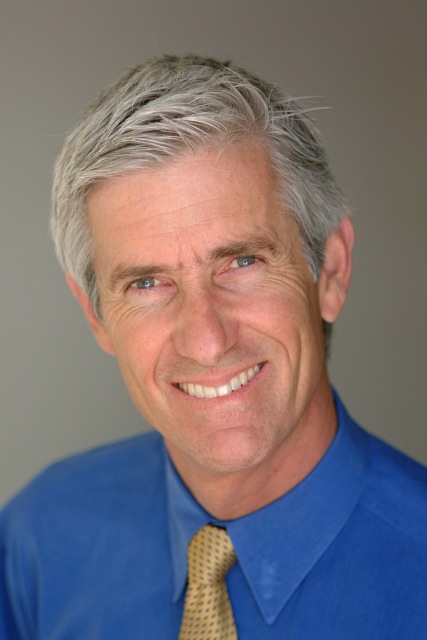

“The new, larger Versamill 5X200 is heavier than its predecessor, provides increased axes-travels and features a 15-station Automatic Tool Changer,” says Steve Braykovich, President of Axsys Dental Solutions. “The 5X200 features our own proprietary work-holding system, which provides significantly greater rigidity, accuracy and repeatability than the standard offering."

Complimented by finely tuned CAD libraries and machining templates, derived from nearly 40-years of manufacturing experience, Axsys’ unique solution enables faster machining times, razor-sharp margins, greater tool life, and minimum post-machining bench-work, Braykovich says.

The Versamill 5X200’s superior construction enables it to machine a wide range of materials including zirconia, titanium, chrome cobalt, resin, wax, and lithium disilicate and is ideally suited for complex indications including bridges, custom abutments, and dental bars.

“A common misconception is one has to spend hundreds of thousands of dollars on a 'big machine' to effectively machine complex restorations made of hard materials," Braykovich says. “Don’t let its small footprint fool you; this is one serious machine that can get the job done, in many cases more effectively - for one-third the cost of 'full-frame' machines."

For more information, contact Axsys Dental Solutions at 1-855-687-7941 or visit axsysdental.com.